Aerospace Materials: A Journey Through Time

Learn about the history of materials in aerospace

10th May 2024

6 min read

Daniel Bevan

Daniel Bevan is a professional engineer and co-founder of White Crab Systems

Caption: SpaceX rocket launch

Aerospace materials: A journey through time

Introduction

The history of aerospace materials is a journey of innovation, from the early days of aviation to today's cutting-edge technology. In this blog you will be taken through some of the key milestones in aerospace materials, starting with the Wright brothers and progressing through to future materials that could revolutionize the industry. By examining specific examples throughout history, we can understand how materials have played a pivotal role in the evolution of aerospace.

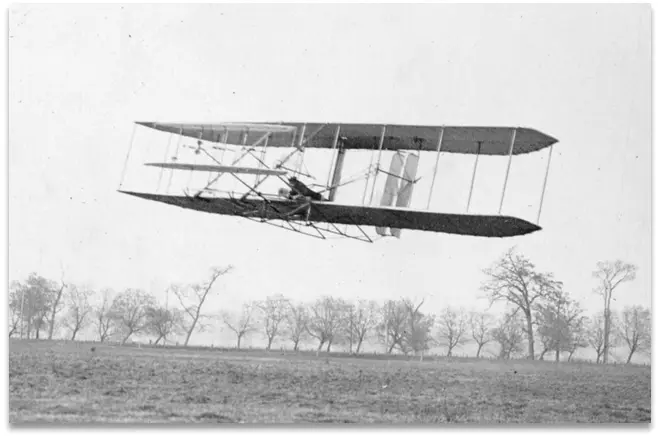

The Wright Brothers Plane (1903)

It would only be right to start in 1903 with the Wright Brothers plane. Kicking off what would later become the 300-billion-dollar aerospace industry. The first successful powered flight by the Wright brothers in 1903 relied on simple materials. The Wright Flyer was constructed primarily from wood and fabric. The frame was made of spruce, a lightweight yet sturdy wood, while the wings were covered in muslin fabric. This combination of materials was not only readily available but also allowed for the precise construction needed for the Flyer to achieve lift.

Can Metal Fly? (1915)

The Junkers J1, developed in 1915 during World War I, was the first all-metal aircraft. Nicknamed the “flying tank” it marked a significant departure from wood and fabric, using steel for its frame and aluminium for its skin. The design featured corrugated steel in the joints to increase the structural integrity and later versions used an aluminium and brass alloy, Duralumin to save weight.

Super Alloys (1941)

The development of jet engines during World War II required materials that could withstand extreme temperatures and stress. Superalloys, such as nickel-based alloys, emerged as a solution. A super alloy is a material that can successfully operate at a high percentage of their melting point. For example, the nickel-chromium alloy, Inconel can operate at around 2000C with it’s melting point at around 2400C. The Whittle W.1 engine, one of the first jet engines was used in the Gloster E.28/39, it incorporated superalloys for the first time to endure the high heat and mechanical loads. This breakthrough allowed for the creation of high-performance jet aircraft. Today Inconel still accounts for up to 50% of the weight of modern turbojet engines with the common areas being rotor blades, discs and casting that experience the highest temperatures and pressures.

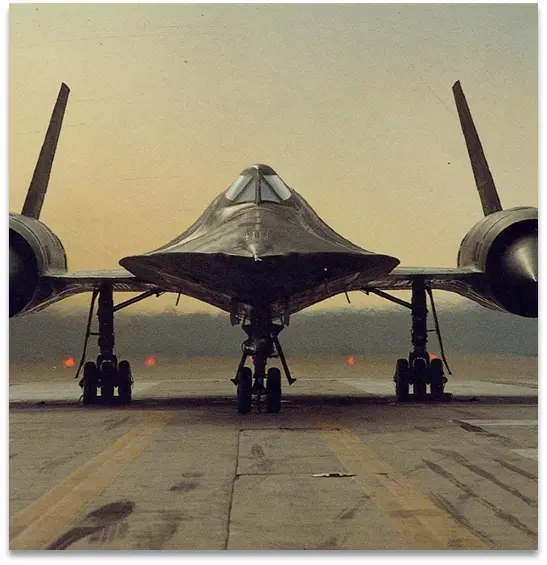

The Blackbird (1966)

The SR-71 Blackbird, developed in the 1960s, was a marvel of engineering, capable of reaching speeds over Mach 3. To achieve this, it used titanium extensively in its construction, up to around 85% of the total weight of the plane was made from titanium. Titanium's high strength-to-weight ratio and exceptional heat resistance made it ideal for the Blackbird's high-speed flight. This reliance on titanium allowed the aircraft to endure extreme temperatures generated by air friction at high speeds.

The heavy reliance on titanium did create issues with manufacturing and procurement during the project. Titanium is very hard, and the manufacturing processes destroyed many machining bits that cost the project enormously in terms of time and money. The CIA also had to purchase titanium secretly using shell corporations from Russia due to massive shortages in the USA. The Blackbird’s ingenious design had loose fittings at room temperature such that when the plane heated up due to the speed, the metal would expand, and the plane would be structurally sound.

Space Age (1980s)

The Space Shuttle, first launched in 1981, used advanced ceramic tiles for its Thermal Protection System (TPS). These ceramic tiles were designed to withstand the 1650C heat of re-entry into Earth's atmosphere. Coated LI-900 silica ceramics were made from heating pure quartz sand, and then glued to an under-skin made of Kevlar. The tiles' unique properties allowed them to absorb and dissipate heat while protecting the shuttle's structure. This application of advanced ceramics was critical for the success of the Space Shuttle program.

The process was not without issue however as during manufacture, the glue would sometimes set too quickly for the fitters to accurately place the panels. This being the 1980s, the solution was for the fitters to spit into the glue mixtures to dilute it and allow it to set slower. This however was a major quality issue that caused panel failures in many of the finished tiles, and a reminder of the importance of designing for manufacture as well as ensuring shortcuts aren’t taken.

Commercial (2000s)

Airbus introduced a novel use of indium tin oxide (ITO) in its aircraft in the early 2000s. . Depending on Oxygen content ITO is classed as either an alloy or a Ceramic, however film can be highly transparent and conductive. Airbus used ITO in smart windows that can adjust their tint based on external conditions. This technology allows the pilots to control the amount of light entering the cabin, reducing the need for mechanical window shades. It also can act as a defroster to prevent ice build-up on the windscreen. This use of ITO represents the integration of advanced materials with modern aerospace design.

5th Generation Fighter (2010s)

The F-35 Lightning II, a fifth-generation fighter jet, is made of around 35% carbon fibre composites. When asked about the reason for this, Don Kinard, technical deputy for the Joint Strike Fighter Production Operations Lockheed Martin “we could make a higher percentage but need to think of “why”. Carbon fibre was used in the skin of the aircraft as the internal fuselage structure was designed using traditional methods to remain inside the project cost and reduce complexity.

The F35 incorporates sapphire for its optical components, including the Electro-Optical Targeting System (EOTS). Sapphire is highly temperature resistant and resistant to scratches and abrasions, making it ideal for protecting sensitive optical equipment. The man-made sapphires are a lot larger than those used in jewellery and need to be carefully extruded to maintain clarity.

Future Materials

Looking to the future, materials like graphene hold immense potential in the aerospace industry. Graphene is a single layer of carbon atoms arranged in a hexagonal lattice, offering exceptional strength, conductivity, and flexibility. It has the potential to revolutionize aerospace by enabling lighter and more efficient structures, advanced electronic systems, and enhanced thermal management.

Other future materials, such as carbon nanotubes, metallic glasses, and advanced composites, are also being explored for their unique properties and potential applications in aerospace. These materials could lead to more durable aircraft, improved fuel efficiency, and new capabilities in aerospace technology.

Conclusion

The journey through the history of aerospace materials reveals a continuous drive for innovation and improvement. From the Wright brothers' use of wood and fabric to future materials like graphene, each milestone has contributed to the evolution of aerospace technology. As the industry continues to explore new frontiers, the role of advanced materials will be more crucial than ever in shaping the future of aerospace.

Deploy Next.js on Kubernetes Step 1: Image Building & CI/CD

David Hazra

25th July 2024

Search Engine Optimization Part 1: How Does It Work?

Kai Cockrell

5th July 2024

Weights and Biases Website Design Review

David Hazra

6th June 2024

Visual Storytelling in Web Design

Daniel Bevan

27th April 2024

Visual Hierarchy: Controlling Your Users Focus

Kai Cockrell

19th April 2024

Gestalt Principles: Capturing Attention in Web Design

Kai Cockrell

12th April 2024

Linguistics and LLMs: Understanding Language

Kai Cockrell

11th April 2024

Databases on Kubernetes (Part 1)

David Hazra

10th April 2024

Inside UK Chip Designer ARM's Soaring Share Price

Daniel Bevan

19th February 2024

© 2024 White Crab Systems LTD. All rights reserved.